Our involvement in the client’s project at an early stage of product development avoids many problems in the implementation phase and the subsequent production process, which directly translates into the life of the final product on the sales market.

- Plastic Part Design

- Plastic Part Prototyping

- Demonstrative and Functional Prototypes Manufacturing

- Design For Manufacturing Analysis

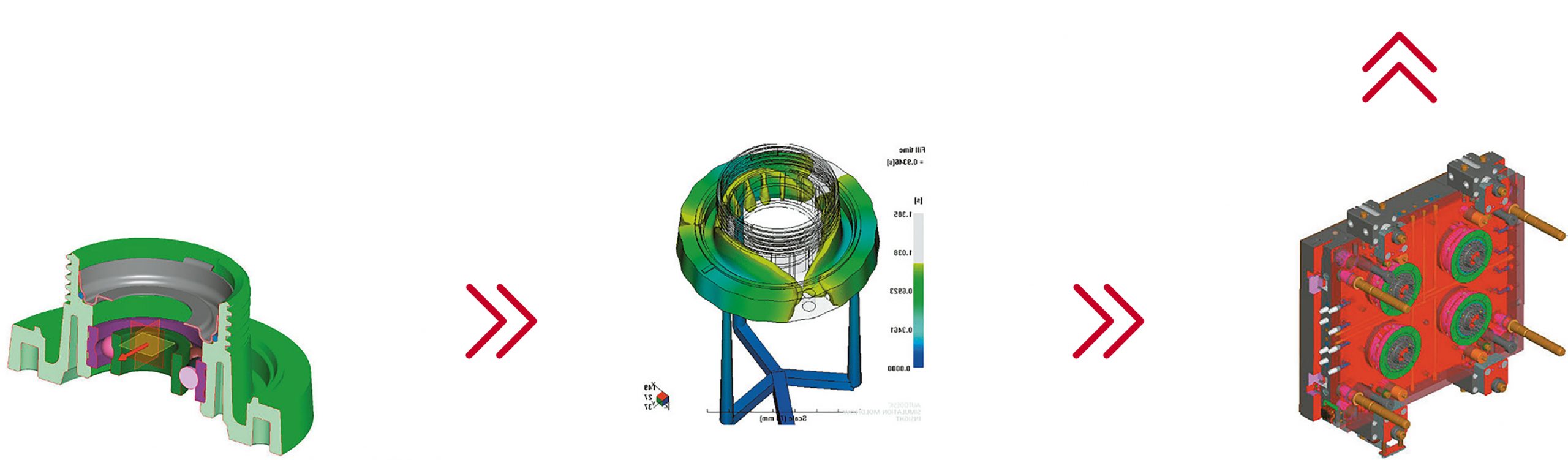

- Moldflow Analysis

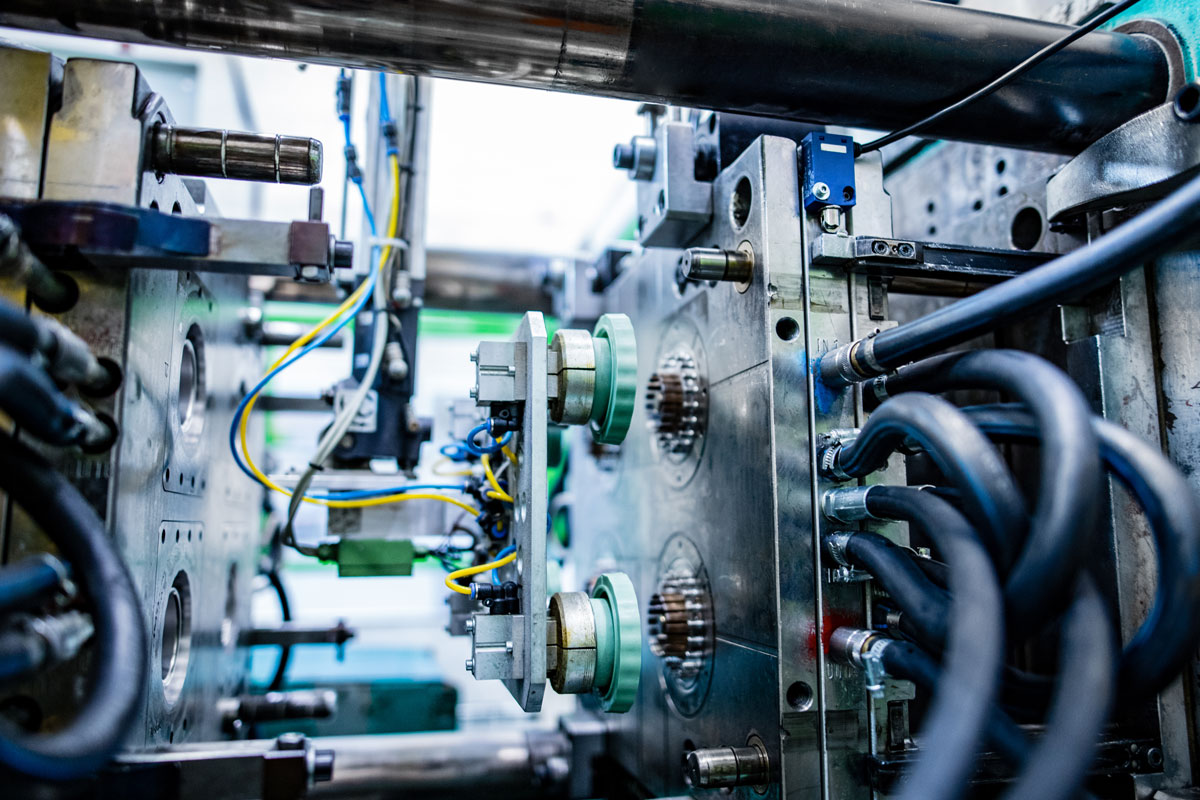

- Injection Molds Manufacturing

- Production Process Flow Design

Those are the actions that we are taking as a response to market demands. Due to company growth, we have established The Research and Development Department where we are able to support thru product lifetime use

Our engineers cooperate directly with R&D departments on the side of our clients by designing and advising on the project. They provide professional support in the design of specialized production equipment. The involvement of PLASTMER as a supplier at the initial stage of the project allows our clients to create better products, use resources more efficiently, and raise internal qualifications – design of aesthetic and functional plastic products.

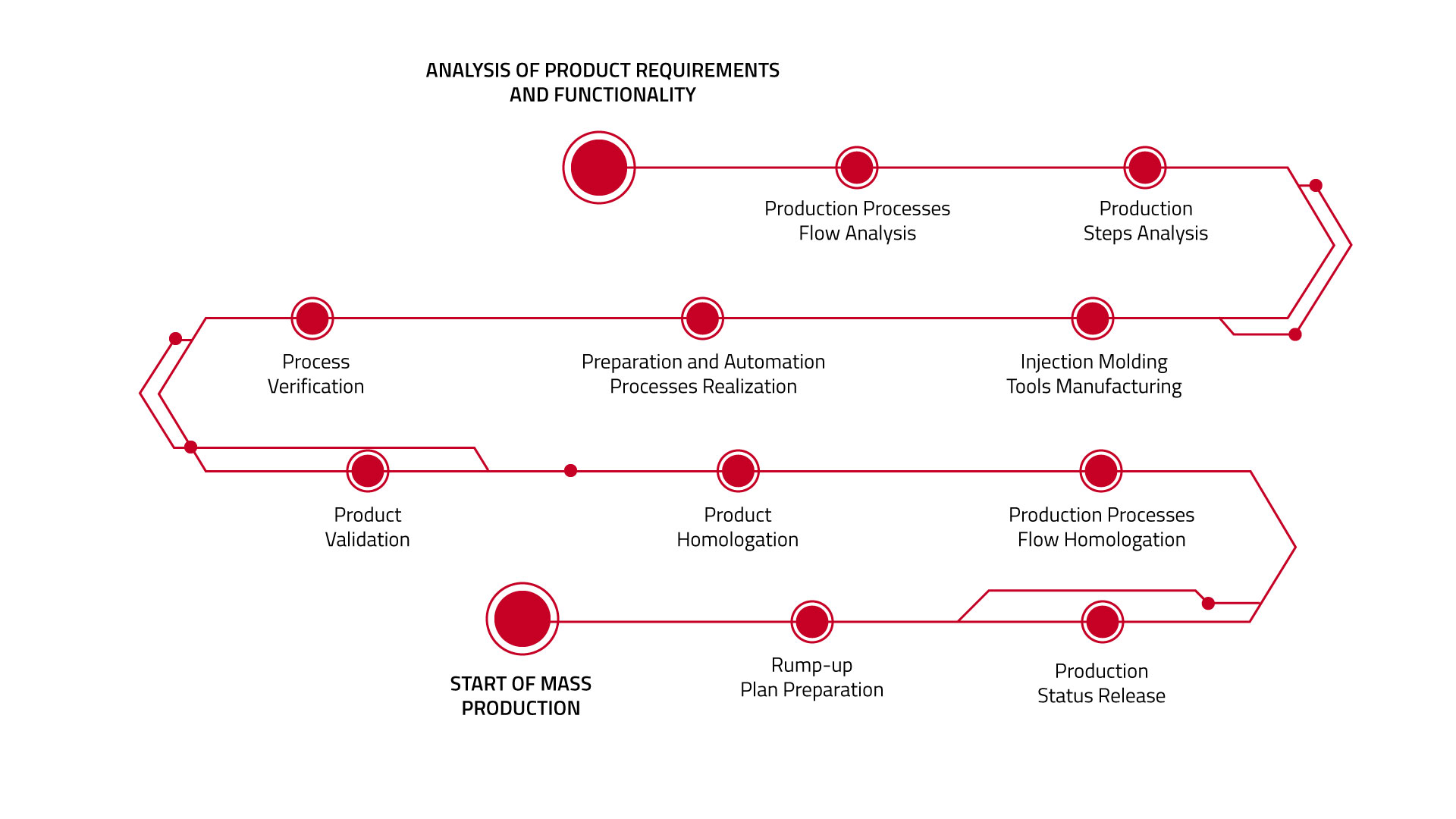

In cooperation with Plastmer, each project begins with the joint definition of product functional requirements and its intended use. After design arrangements, the next steps are technological analysis of selected manufacturing processes, construction of final equipment, verification of processes and their validation.

Each product implementation for mass production carried out by Plastmer ends with the final verification trials and process. We proceed with preseries and manufacturing verification trials in final production conditions. Having positive process homologation we are focusing on final delivery plan implementation.

PRODUCT DEVELOPMENT IN PLASTMER

We provide comprehensive product development for our clients from many industries.

Defining measurable and specific requirements for a new product is crucial for its proper design and further functionality. We know how important and complicated it is to define the requirements of the plastic elements or other technical material – this is the reason why we are offering our technical support through product development and its lifetime. We offer comprehensive solutions – new product design, functional and technological analysis, design&construction of final production equipment that will guarantee stable mass production

PROTOTYPING AND FEASIBILITY ANALYSIS

The key to optimal design and maintaining the full functionality of new product is an initial feasibility study and testing phase based on prototypes. By those proactive actions, we are able to guarantee the best achievable solution.

Performing a detailed feasibility study is strongly recommended in plastic part design evaluation.

Using our own prototyping machines, we perform both – demonstrative and functional prototypes. Carrying out DFM executive analyzes and moldflow analyzes allows Us to minimalize design risk and the need for further modifications in mass production manufacturing tools.

As a result, we get a fully optimized end product ready for implementation in the sales market.

The recommended workflow for your product development:

- PDR – Preliminary Design Review – discussion about product requirements

- DFMEA – Design Failure Mode & Effects Analysis

- PFMEA – Process Failure Mode & Effects Analysis

- DFM – Design For Manufacturing

- Moldflow

- Mass production tool manufacturing

- Verification of subcomponents and final products

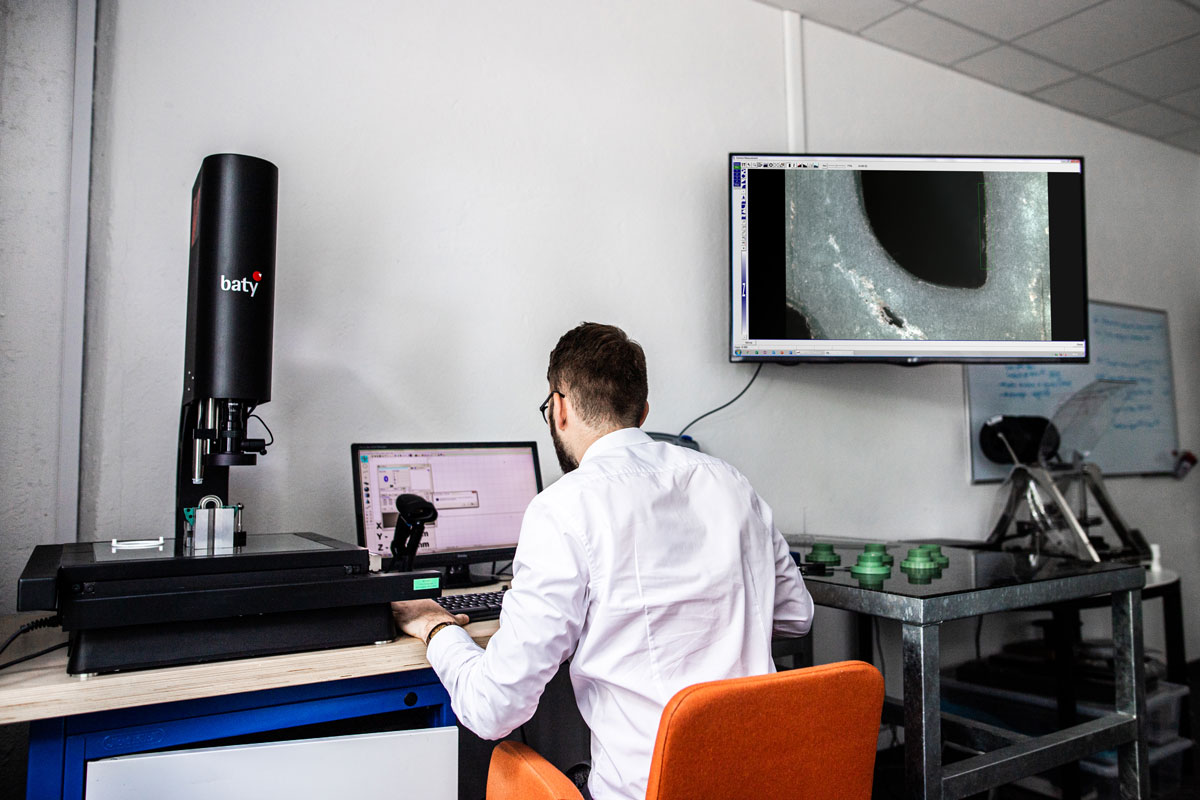

Product development and it’s evaluation during lifetime needs detailed measurements and analysis. Evaluation of demanding design in case of quality in aesthetics and shape accuracy requires to scan and compare many design cases to find the best solution for our clients.

Having in our portfolio 3D scanning service is an added value for product development in PLASTMER

DEVELOPMENT DIRECTIONS

We believe that continuous development is the key to the future. All over the time we develop and implement new technologies for mass production – printing / decoration technology and

new production technologies:

Digital Printing

In Mold Labeling

Blow-Molding

Over-Molding

RESEARCH LABORATORY

We have measuring equipment – optical and contact enabling detailed dimensional analysis as well as observation of phenomena occurring on the surface and inside of produced elements. In response to our clients’ needs – we also provide 3D scanning services for elements produced for the needs of accurate surface structure and shape analyzes.

Special Products

For special processes we implement extraordinary production conditions to ensure stable, repeatable production and highest quality level of manufactured products.