Ultrasonic welding is an industrial method of joining materials using acoustic waves as a carrier of mechanical energy for materials placed between a vibrating tool (sonotrode) and anvil. Due to the pressure of the elements and the action of waves, there is friction between the particles, plasticization, and melting of the materials, which causes a combination of materials.

Advantages:

- Energy-saving

- Harmless to the environment, elimination of poisonous adhesives and solvents,

- Short connection time (fraction of a second),

- High efficiency

- A convenient and clean way to connect,

- The ability to combine different materials.

Resistance Welding

The method of joining materials by pressure with electrodes in which heat is generated as a result of the current flow.

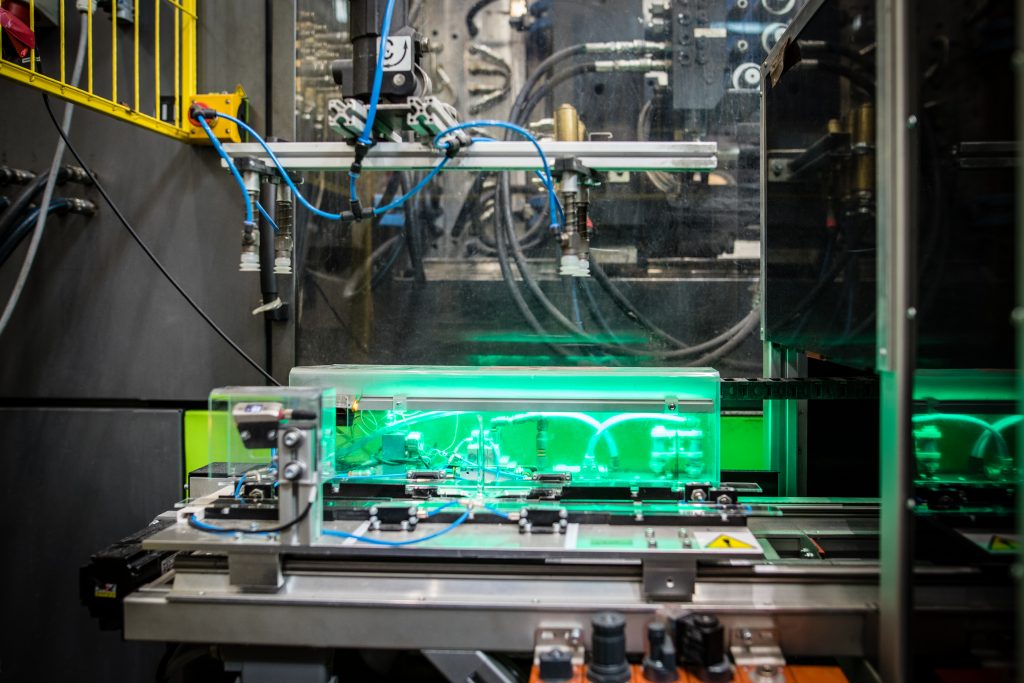

LASER CUTTING CO2

Thanks to high precision, speed of operation and repeatability, the method of laser cutting of plastics is at the forefront of our solutions. It does not destructively affect the structure and properties of the material being cut. Laser cutting technology does not cause the appearance of micro-cracks while maintaining the aesthetics of the cutting edge.

Marking:

In our company, we can also use owned laser stations to mark / engrave products for individual customer needs.

ULTRASONIC CUTTING

The method used for precise and clean cutting process guarantees almost lossless separation of cut surfaces.

WRAPPING

Using the experience in building comprehensive automation solutions for specialized processes, we offer the possibility of personalized wrapping of products for their further protection and the application of specialized technical tapes.

STAMPING (metalworking)

As part of contract production, we carry out orders related to plastic forming aimed at shaping, separating and joining sheets of metal, foil, and plates. The manufactured metal elements are used for further assembly processes with non-metal elements.