One of our speciality is plastic parts production that requires special processing.

We produce technical and aesthetical parts for household appliances as well as automotive industry taking into account the specifics of a given material.

The main materials that we process are ABS / PMMA / POM / PA / PP / PS / MABS / PC.

Plastics processing – Wroclaw – we operate locally on this market. At our headquarters equipped with a wide range of injection molding, assembly, and decorative machines, we are able to provide comprehensive customer service. Do you need support in terms of print or injection of plastics in Wroclaw? Contact us, we’ll be happy to help!

INJECTION 1K/2K

We manufacture the injection tools and produce on conventional injection machines, 2K injections, overmolding of metal/plastic inserts as well as using blow-molding and mu-cell technology.

Multi-component injection gives the opportunity to combine the properties of individual components together – different materials and colors in the same injection mold. It is possible to process several types of materials in one manufacturing process, which eliminates the need for additional joining processes and subsequent assembly. Reducing production costs and reducing production time is a key aspect for us in projects.

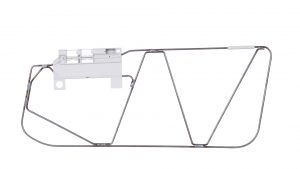

OVERMOLDING

It is a structural solution that permanently connects elements (usually metal) with plastic, thanks to which we obtain very good functional properties of the products. In our company, we perform overmolding of metal and joining of plastics. As a result, we receive elements with very high strength and high utility values.

Mu-Cell

It is a technology that allows the production of microporous materials. Uses atmospheric gases to produce microcellular foams with closed pores. The ideal solution for low-deformation technical components with low weight. An additional advantage is the possibility of using this technology without additional modifications to the mold.

Benefits compared to traditional injection molding

- Product weight reduction

- Cycle time reduction

- High quality – reduction of sink marks and production of dimensionally stable goods

- Reduction of clamping force – low pressure injection molding

- Increased cavities filling efficiency

- Lowering costs

Blow-molding

The ideal solution for empty products: containers, canisters, toy items, construction items, utility items and foil in the form of tubular sleeves.

Blow molding is the process of forming thermoplastics, the stretching operation can take place in the transverse, longitudinal or in both directions simultaneously. One of the factors of the stretching medium is air feed under increased pressure.